The hub bearing is mainly forbearing and accurately guides the rotation of the hub. It bears both the axial load and the radial load and is a very important component. Our company has been manufacturing wheel bearings for more than 15 years and has a relatively deep understanding of the characteristics and development of this product. I will introduce wheel bearings to you through this article.

Overview of development trends

1 Development overview

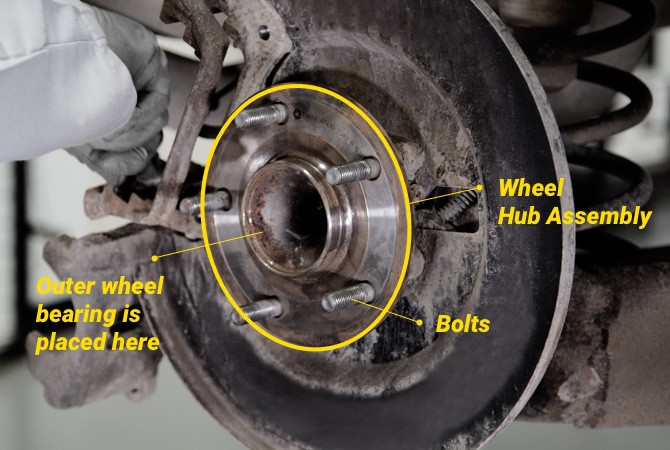

The wheel hub bearing of the car is installed in the wheel hub part of the car wheel. In order to improve the performance of the wheel hub bearing, the wheel hub bearing has been developed from the early two single-row tapered bearings to the double-row tapered roller bearing and the double-row angular contact ball bearing, and then developed from a simple bearing to a The hub bearing unit with the bearing as the core.

2 Composition and its characteristics

The first generation of hub bearings

It is composed of two single-row tapered bearings. The main function is to support the rotation of the wheel. It needs to be adjusted to ensure that the bearing has a reasonable clearance during installation;

The second generation of wheel hub bearings

It is a hub bearing unit composed of double-row tapered roller bearings or double-row angular contact ball bearings. A high-performance special grease is added to the inside of the bearing. The installation is unitized, and the clearance of the bearing unit does not need to be adjusted;

The third generation wheel hub bearing unit

The main structure of the product is two double row angular contact ball bearings with a flange structure, one flange is connected with the hub of the car, the other flange is connected with the suspension, the inner hole is connected with the drive shaft, and the bearing unit has a synchronous speed measuring plate and The high-performance sensor is the signal acquisition unit of the car ABS system and is a mechatronic product with high technical content;

Fourth-generation wheel hub bearing unit

One of the inner sleeves or outer sleeves is an integral part of the drive shaft, and the structure is more compact than the third generation. The third and fourth-generation wheel hub bearing products are mainly used for cars with ABS systems and are medium and high-end cars and high-end business wheel hub bearings. development trend

All uploads are secure and confidential

All uploads are secure and confidential

One Response

Thanks for your blog, nice to read. Do not stop.